High Performance

Thermoplastic Stock Shapes for Machined Parts

At Quantum, we specialize in the manufacturing of extruded high-performance thermoplastic plastic stock shapes for machined parts. The machined parts made from our products are primarily utilized in aerospace, defense, electronics, semiconductor, healthcare, and energy industries.

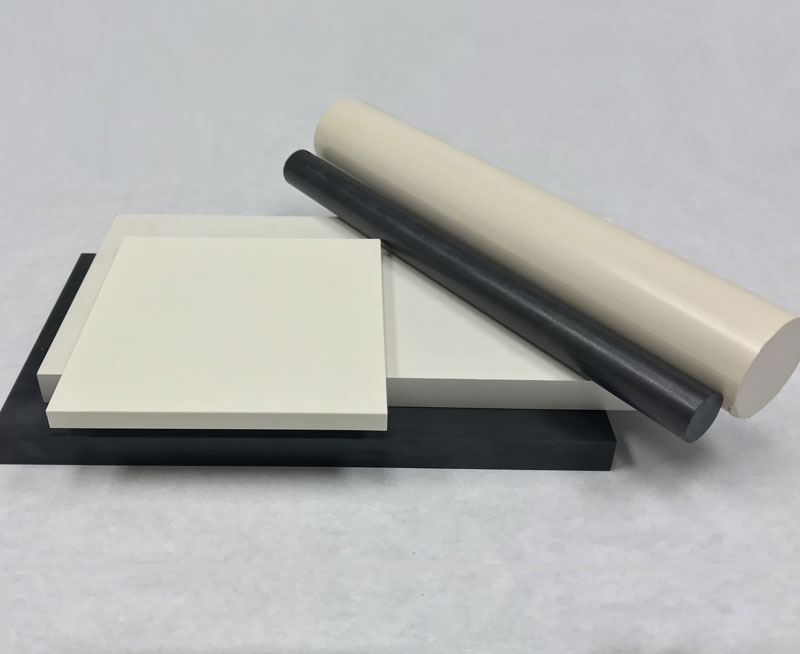

Whether your application requires neat polymers or enhanced properties for electrical, mechanical, thermal, or tribological applications, we have the solution. Our extensive range of materials, include. PEEK, ULTEM™, PVDF, PPS, Delrin® 100AF, and Delrin AFDE588. These polymers are also available with fillers and reinforcements like glass, carbon and aramid fibers, carbon nanotubes, graphite, and PTFE.

Our Products

Polyetheretherketone (PEEK) offers the highest chemical resistance of any semi-crystalline plastic with excellent retention of mechanical properties up to 570°F (300°C).

Polyphenylene sulfide (PPS) is suitable for high performance structural components requiring thermal stability, structural integrity, high dimensional stability and exceptional resistance to a broad range of acids, alkalis, ketones and hydrocarbons

Polyvinylidene fluoride (PVDF) is a highly non-reactive and pure fluoropolymer. PVDF is generally used in applications requiring the highest purity, strength, and resistance to solvents, strong acids, weak bases, and low smoke generation during a fire event.

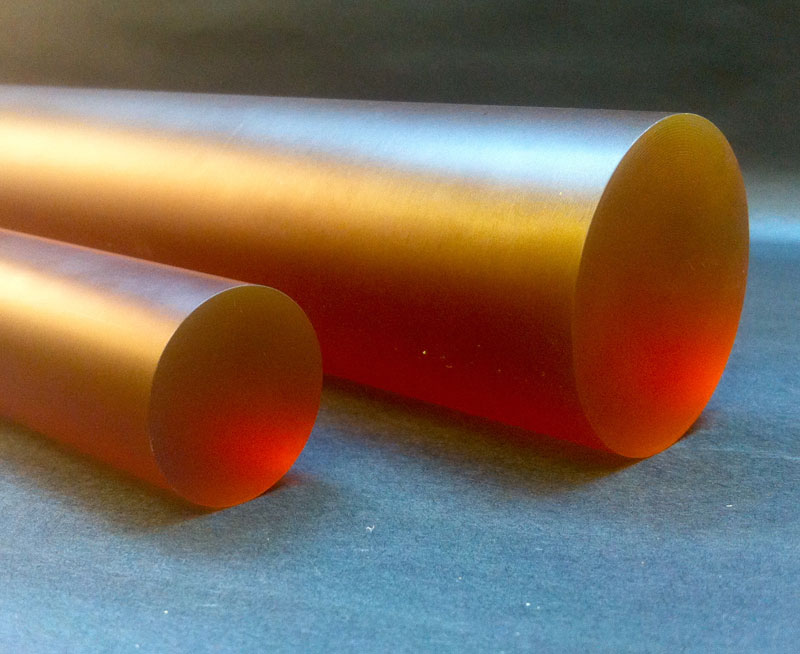

The ULTEMTM family of amorphous thermoplastic polyetherimide (PEI) resins offers outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance.

PTFE filled Polyoxymethylene Homopolymer (POM-H PTFE) is the semi-crystalline thermoplastic of choice for impact and wear resistance in a wide range of industrial and mechanical applications.

Modern designs

0

Projects Completed

0

Happy Customers

0

Building Permits

0

For

technical assistance

ABOUT US

We manufacture and sell engineering and high performance thermoplastic stock shapes for machined parts. Our products are extruded from prime raw materials in our plant in Newark, Delaware, USA.

CONTACT US

- Toll: +1.877.737.7012

- Ph: +1.302.737.7012

- Fax: +1.302.737.7035

- sales@quantum-aep.com

- Quantum Polymers Corp.

211 Executive Dr, Suite 1,

Newark, DE 19702

Follow

© 2024 Quantum Polymers. All rights reserved.