Products

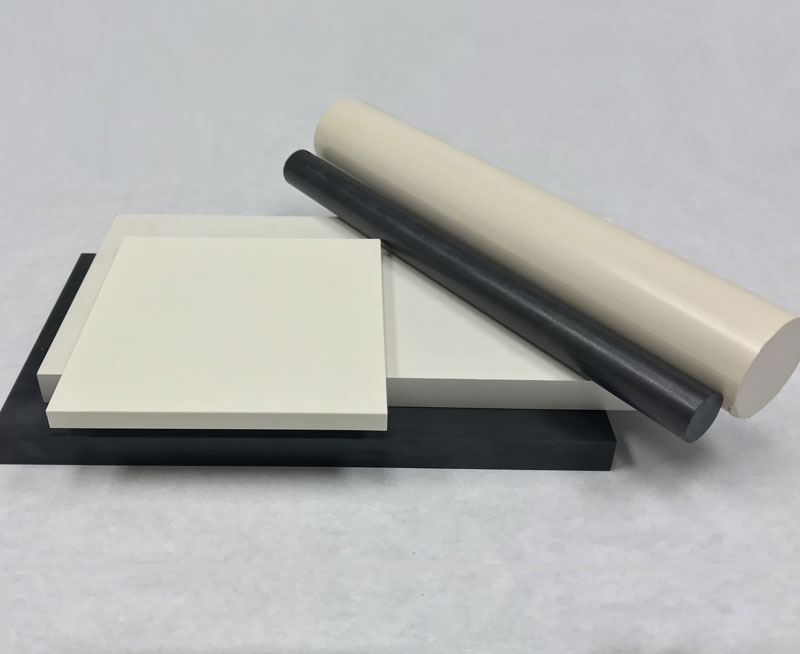

High Performance Plastics Rods and Plates

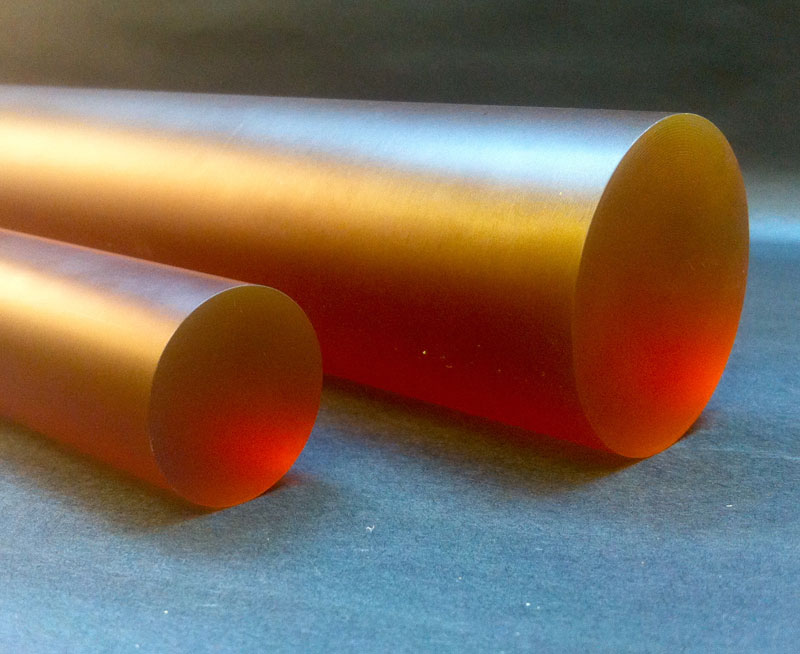

Polyetheretherketone (PEEK) offers the highest chemical resistance of any semi-crystalline plastic with excellent retention of mechanical properties up to 570°F (300°C).

Polyphenylene sulfide (PPS) is suitable for high performance structural components requiring thermal stability, structural integrity, high dimensional stability and exceptional resistance to a broad range of acids, alkalis, ketones and hydrocarbons

Polyvinylidene fluoride (PVDF) is a highly non-reactive and pure fluoropolymer. PVDF is generally used in applications requiring the highest purity, strength, and resistance to solvents, strong acids, weak bases, and low smoke generation during a fire event.

The ULTEMTM family of amorphous thermoplastic polyetherimide (PEI) resins offers outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance.

PTFE filled Polyoxymethylene Homopolymer (POM-H PTFE) is the semi-crystalline thermoplastic of choice for impact and wear resistance in a wide range of industrial and mechanical applications.

Our FAQS

Quantum is an American company. We are technically innovative, consistently leading the industry with new products in new and emerging markets. We are agile, focused and quick to adapt to the ever-changing marketplace.

Yes, each and every product purchased from Quantum comes with a certificate of compliance with full traceability of the resin lot number, production batch number, and date of manufacture.

Currently, Quantum uses only the extrusion process for manufacturing of its products.

Yes. All products are annealed post-extrusion, utilizing Quantum’s proprietary process. Annealing is critical for ease of machining and final part surface smoothness.

All of our stock shapes – rods, and plates – are manufactured in the United States in our 23,000 square foot facility in Newark, Delaware.

No, our focus is on our core competency which is to provide the best quality extruded shapes. Unlike many of our competitors, we do not believe in competing with our machine shop customers. We believe in supporting a healthy manufacturing ecosystem in the U.S.

It is important to know that every stock shape manufactured by Quantum is extruded from the best quality raw material sourced directly from the resin manufacturers. Secondly, our manufacturing equipment is optimized for the intricacies of extruding high temperature polymers. This allows for porosity-free stock shapes, which are especially critical for large diameter rods and thick cross section plates. A porosity-free shape is essential to flawless machining. Lastly, we anneal 100% of our stock shapes with our proprietary annealing process that results in machined parts with no residual stress.

For

technical assistance

ABOUT US

We manufacture and sell engineering and high performance thermoplastic stock shapes for machined parts. Our products are extruded from prime raw materials in our plant in Newark, Delaware, USA.

CONTACT US

- Toll: +1.877.737.7012

- Ph: +1.302.737.7012

- Fax: +1.302.737.7035

- sales@quantum-aep.com

- Quantum Polymers Corp.

211 Executive Dr, Suite 1,

Newark, DE 19702

Follow

© 2024 Quantum Polymers. All rights reserved.